You’ve probably heard the terms “generator” and “alternator” before, but what do they actually mean? Most people don’t know the difference between a generator and an alternator. And even if you think you do, some key distinctions set them apart.

This article on “Generator Vs Alternator” will briefly introduce you to the alternator and generator and clarify their key differences and similarities. We’ll also explain when it’s best to use each type of technology.

The confusion between the two arises from the fact that while the term alternator has a clear, concise meaning and definition, the term generator is loosely used and has different meanings in different contexts, as discussed below.

- A portable generator comprises an engine, an alternator, and other major systems (like fuel, compression, ignition, lubrication & cooling, and the governor or speed control), while an alternator is a part of the complete machine that is called a generator.

- As you may know, we use Alternating Current (AC) and Direct Current (DC) power in our homes and industrial buildings. An alternator converts mechanical energy specifically to AC electrical power. On the other hand, the generator converts it to DC or AC electrical energy. Hence, the term generator is a general term that can represent any machine that converts mechanical energy into electrical energy, that may be AC or DC. With this definition, an alternator becomes a subset of a generator.

- In common parlance, the term “Generator” is used more for DC generators.

To keep things simple, we will use the approach that, since alternators are clearly defined, anything which is not an alternator is a generator and differentiate them accordingly.

Alternator Vs Generator

What is a Generator?

As introduced above, the generator is a piece of machinery that comes in different shapes and sizes and converts mechanical energy into AC or DC electric power through electromagnetic induction. The generators can be of various types.

- DC generator,

- AC induction generator,

- AC synchronous generator, also known as an alternator.

The different types of DC generators include

- Permanent magnet,

- Self-excited,

- Separately excited generators.

- Series Wound

- Compound Wound

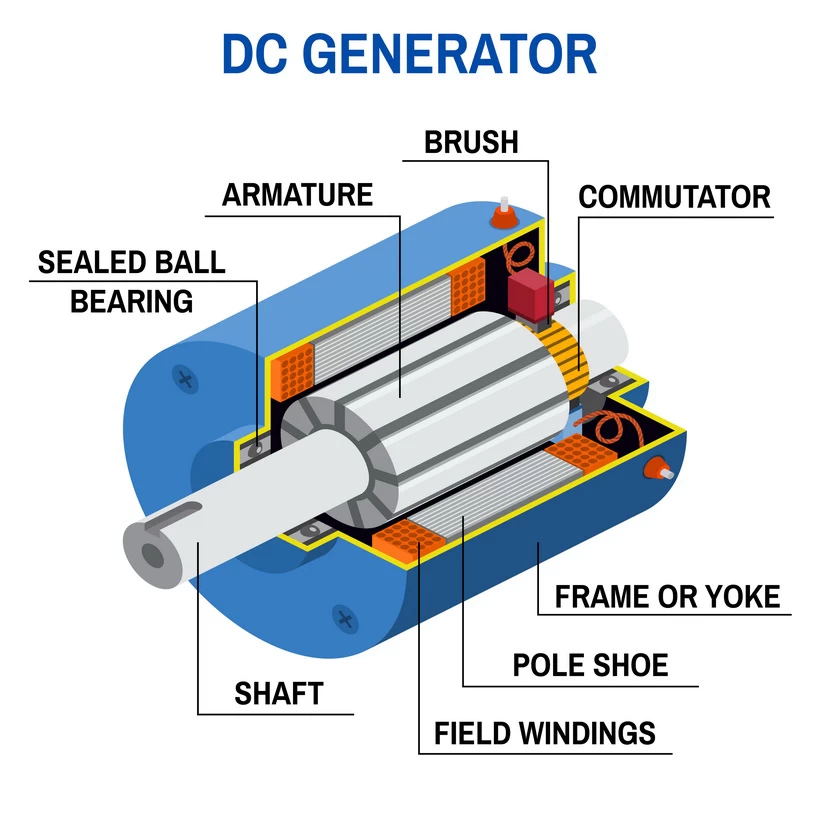

As you can see, alternators are a particular category of generators. The difference between an alternator and other generators lies in their structure and construction. All DC generators and some small AC generators use what is known as rotating armature construction.

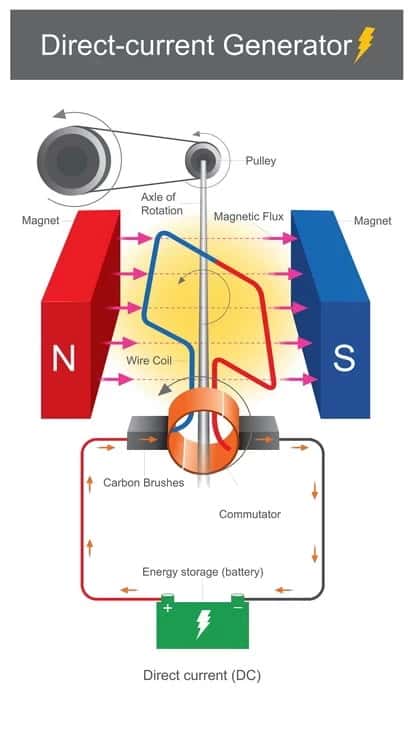

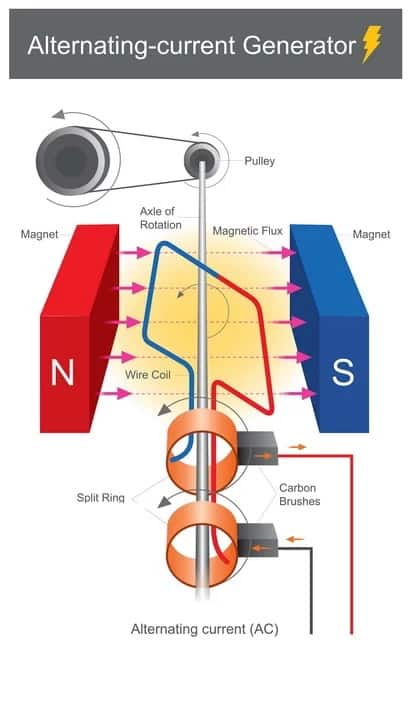

In the rotating armature type machines, the armature winding consists of coiled wires, and spins in a stationary magnetic field, utilizing the mechanical energy of the prime mover to produce voltage, known as electromotive force “EMF.” This power is fed to the loads, either as the “DC power” using the commutator arrangement or as “AC power” using the slip ring arrangement (shown in the below images).

What is an Alternator?

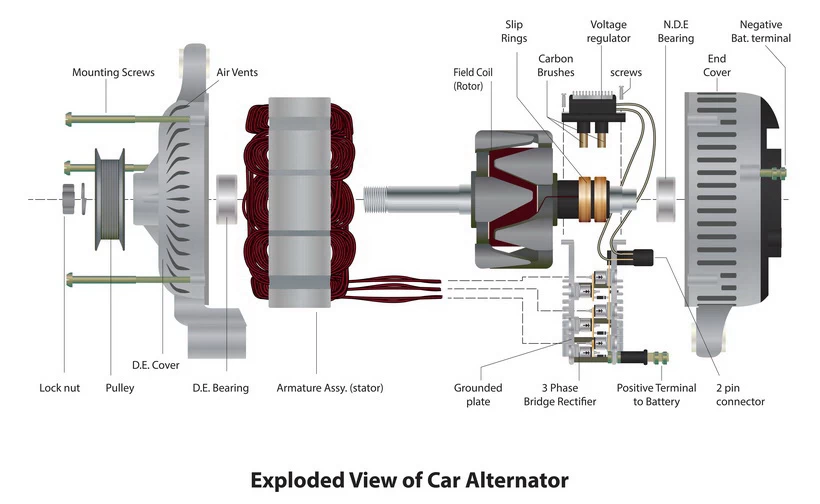

Alternators also utilize the principles of electromagnetic induction and convert mechanical energy to produce electrical power. But, they have rotating field construction in which the armature winding is mounted on the stationary element “stator,” and the field winding on the rotating element “rotor.”

The stator comprises a cast-iron frame to support the armature core. The core carries slots for housing the armature conductors on its inner periphery. The rotor acts as a flywheel and houses alternate north and south poles on its outer rim. It receives DC power at 125 to 600 V through the slip rings, and as the magnetic field spins inside with the rotor movement, it produces a rotating magnetic field.

The rotating magnetic flux gets linked with the stationary armature windings and generates electricity that can be directly fed to the loads.

They are also known as synchronous generators, which means they run at the synchronous speed Ns, given by the equation Ns = 120 F/P, where F is the frequency in Hertz and P is the number of poles in the generator. For 60 Hz, two-pole machine, Ns = 3600 rpm.

Generator Vs Alternator – Applications of the DC generators

Let us quickly apprise you of the major applications of the DC generators

Shunt or Self-excited Generators

- They are used to charge batteries as they can provide a constant voltage output.

- Used in lighting applications.

- Used to provide field excitation to the alternators.

Separately excited Generators

- Their voltage output can vary over an extensive range, making them suitable for laboratory applications.

- They are used in speed control applications of DC electric motors.

Series Wound Generators.

- Used to provide field excitation for regenerative braking applications in DC locomotives.

- Used as boosters to compensate for the voltage drop.

Other applications include electrical razors, toys, motorcycle dynamos, and arc welding applications where constant current and voltage drop are required.

Applications of Induction Generators

The induction generators are used in windmills and micro-hydro power installations, as they have the ability to generate electricity at varying speeds depending on the wind and water flow conditions.

Applications of the Alternators.

It is estimated that more than 99% of the generating machines are alternators due to their advantages over the other types, which we shall discuss in the following section.

- They are used in all commercial electric power plants using hydroelectric, thermal, nuclear, and gas-based fuels to produce large-scale electricity.

- It is used in any standby and portable generator to produce small-scale electricity.

- They are used in diesel-electric locomotives to generate energy that drives the electric motor.

- They are commonly used in automobiles to provide electrical power in vehicles and charge the car battery. Car windows, lights, windshield wipers, and other functions use DC electrical energy to run. Alternators in cars use a rectifier component to convert AC to DC electricity to power all the necessary parts of the car. Before 1960, the DC generators or dynamos were the go-to machines for automobiles.

- Dynamos also produce AC current converted to DC by the commutator, devices requiring extensive maintenance. With the advent of solid-state electronics, it is now preferred to use alternators driven by the belts from the crankshaft and rectify the AC current to produce a 12 V power supply.

Advantages of Alternators

Though alternators are marginally more complex than other generators, their advantages outweigh the complexity to make them the most preferred out of all. Let us see why.

- The alternator’s energy is fed directly from the fixed terminals on the armature to the load. This AC power does not pass through the brush contacts.

DC generators use commutator and brush arrangement. Commutators are split rings against which the brushes rub to collect current, causing heavy wear and tear. The situation is further worsened by the large value of direct current transferred through them. - The alternator’s sliding contact is shifted to low voltage and the low direct current side by using slip rings on the field winding. The arrangement allows a lower grade of insulation with much less wear on the brushes.

- It is much easier to insulate the stationary winding on the armature for higher voltage grades used in high voltage AC power generation. The insulation voltage may be 30KV grade or higher.

- High voltage alternators produce lower alternating current for the same power output, thereby requiring less copper to construct and lower copper losses in operation. This results in lower size, weight, and better efficiency.

- The rotor carries only the field winding to produce a rotating magnetic field. So, the amount of copper and, consequently, the weight of the rotor is much lower than other generators for the same rating. This further improves the efficiency of the alternator over others.

- It is easier to brace the stationary armature windings to prevent deformation by the high mechanical stresses generated by any short circuit in the winding.

- The size and weight of any three-phase alternator are much lower than other generators of the same power rating.

- Alternators are preferred to produce power commercially as it is easy to distribute energy over long distances using transformers to step up or down the voltages.

- The alternator has a more rugged construction and requires less maintenance than any other generator.

Disadvantages of Alternators

Let us look at some of the disadvantages of the alternators:

- They require carefully modulated and controlled excitation voltage to produce electricity at the required output voltage.

- The speed must be maintained carefully to regulate the frequency in the tight band.

- Alternators have system stability issues, unlike DC generators.

Conclusion

The bottom line is that generators and alternators are very similar devices, with a few key differences. The differences are in the construction and arrangement of armature and field windings. Both have their advantages and disadvantages, leading to differences in their applications. Do you have any questions about generators or alternators? Let me know in the comments section below!